Disinfection / Specialty Cleaning

Disinfection for Pathogens

Disinfection for Commercial Facilities

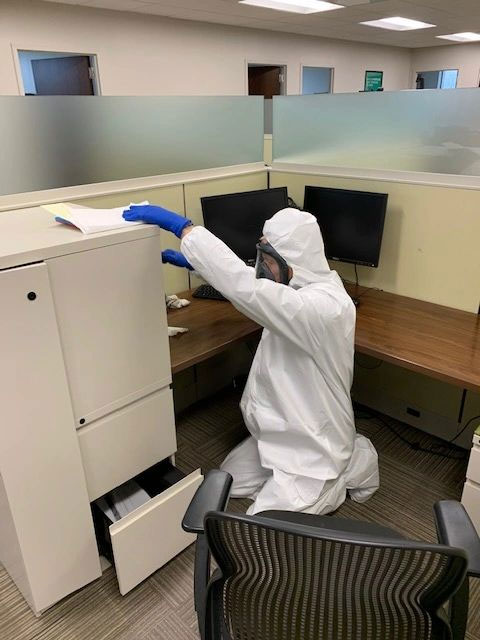

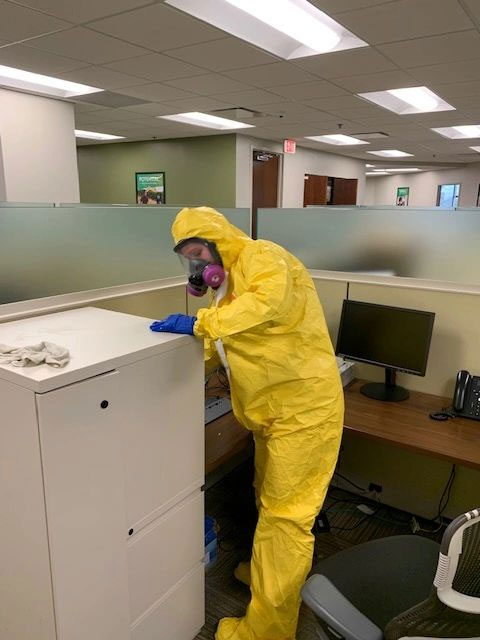

Create a safe environment in your commercial facility with disinfection services from EDS and bring peace of mind to employees and visitors.

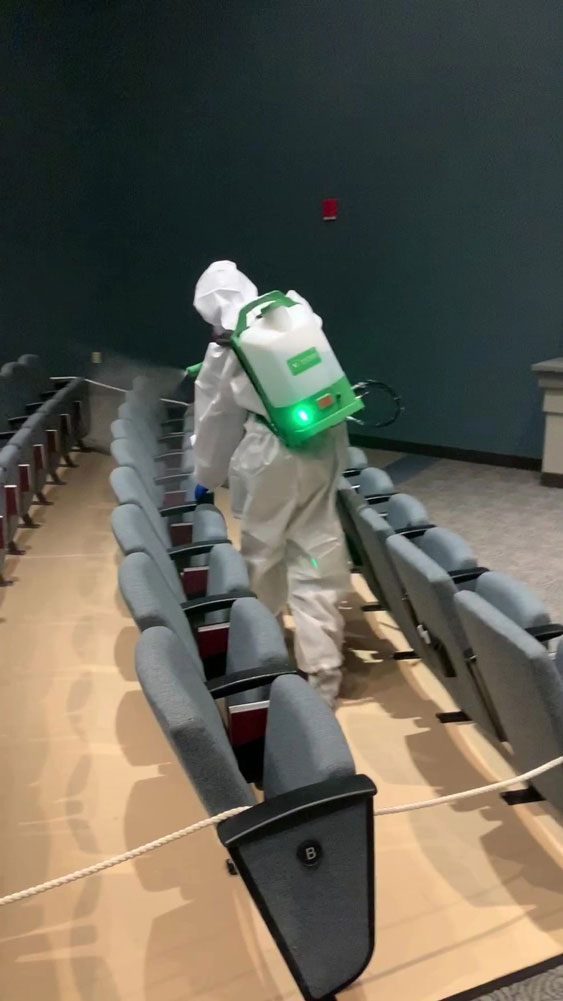

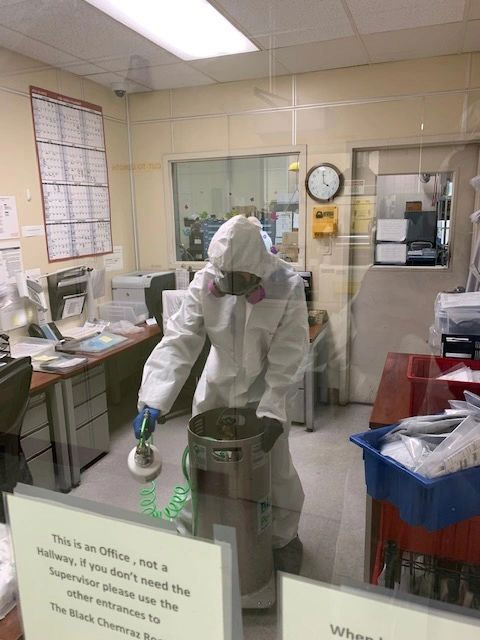

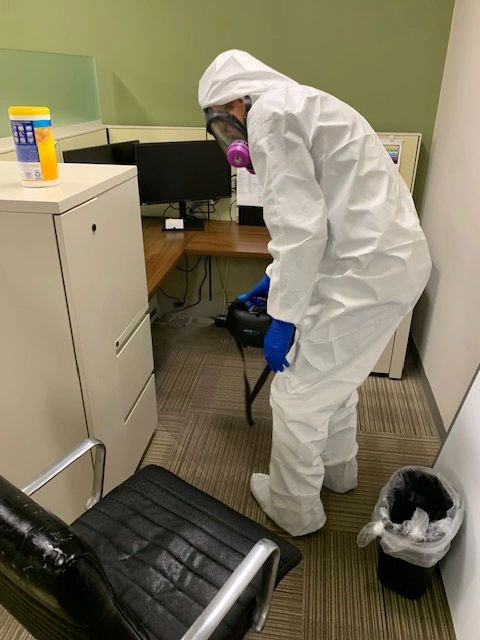

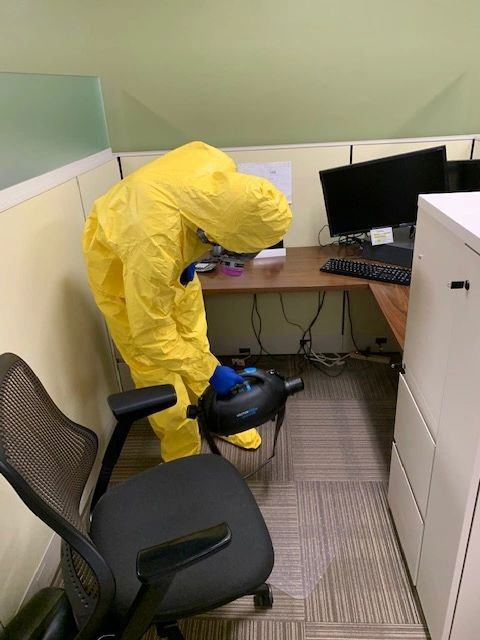

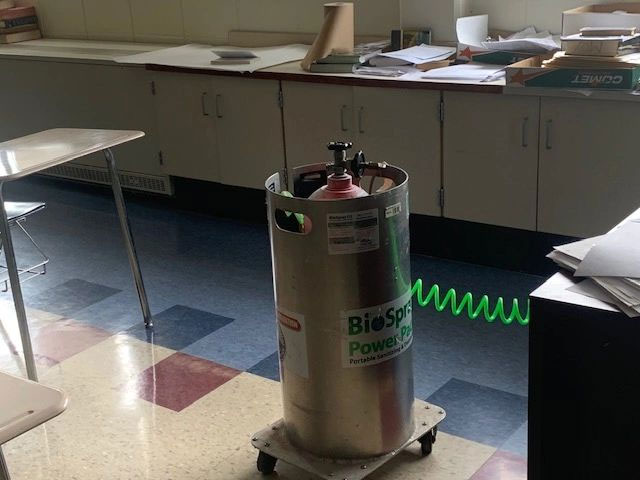

Highly trained and certified technicians (OSHA) provide this important service for your facility. We provide an application of disinfectant using various methods - including electrostatic backpack sprayers, ULV foggers, and atomized sprayers.

EDS works to safely disinfect your facility with EPA-registered products. Our products are CDC-approved. From the smallest office to the largest commercial facility, EDS Biohazard Teams are here to provide the highest quality service to all.

Need ongoing services? Ask about our disinfection maintenance program.

Specialty Cleaning for Commercial Facilities

Cryo-blast cleaning, also known as dry ice blasting, involves using compressed air to propel pellets of dry ice at high speeds to clean surfaces. The dry ice pellets sublimate upon impact, transitioning from a solid to a gas, which removes contaminants without leaving any residue. Industrial facilities integrate cryo-blast cleaning into their maintenance schedules by periodically assessing their equipment and surfaces for buildup or contamination. This method is scheduled during routine maintenance downtimes to minimize disruption to operations. It is particularly favored in industries where cleanliness is crucial, such as food processing and pharmaceuticals, due to its non-abrasive and environmentally friendly nature.

Vapor blasting is a cleaning and surface preparation technique that uses a mixture of baking soda and water stream, effectively removing contaminants, rust, and coatings from various surfaces. The baking soda acts as a gentle abrasive, effectively cleaning without damaging the underlying material. This environmentally friendly method is often used in industries ranging from automotive to historical restoration, ensuring surfaces are left clean and intact. Companies incorporate slurry blasting into their ongoing maintenance programs to ensure equipment and structures remain in optimal condition, thereby extending their lifespan and preventing costly repairs or replacements.